Find The Right Feeder

Specifically designed to accurately and dependably meter dry solid ingredients, feeders can increase efficiency and ensure quality on your production floor.

Specifically designed to accurately and dependably meter dry solid ingredients, feeders can increase efficiency and ensure quality on your production floor.

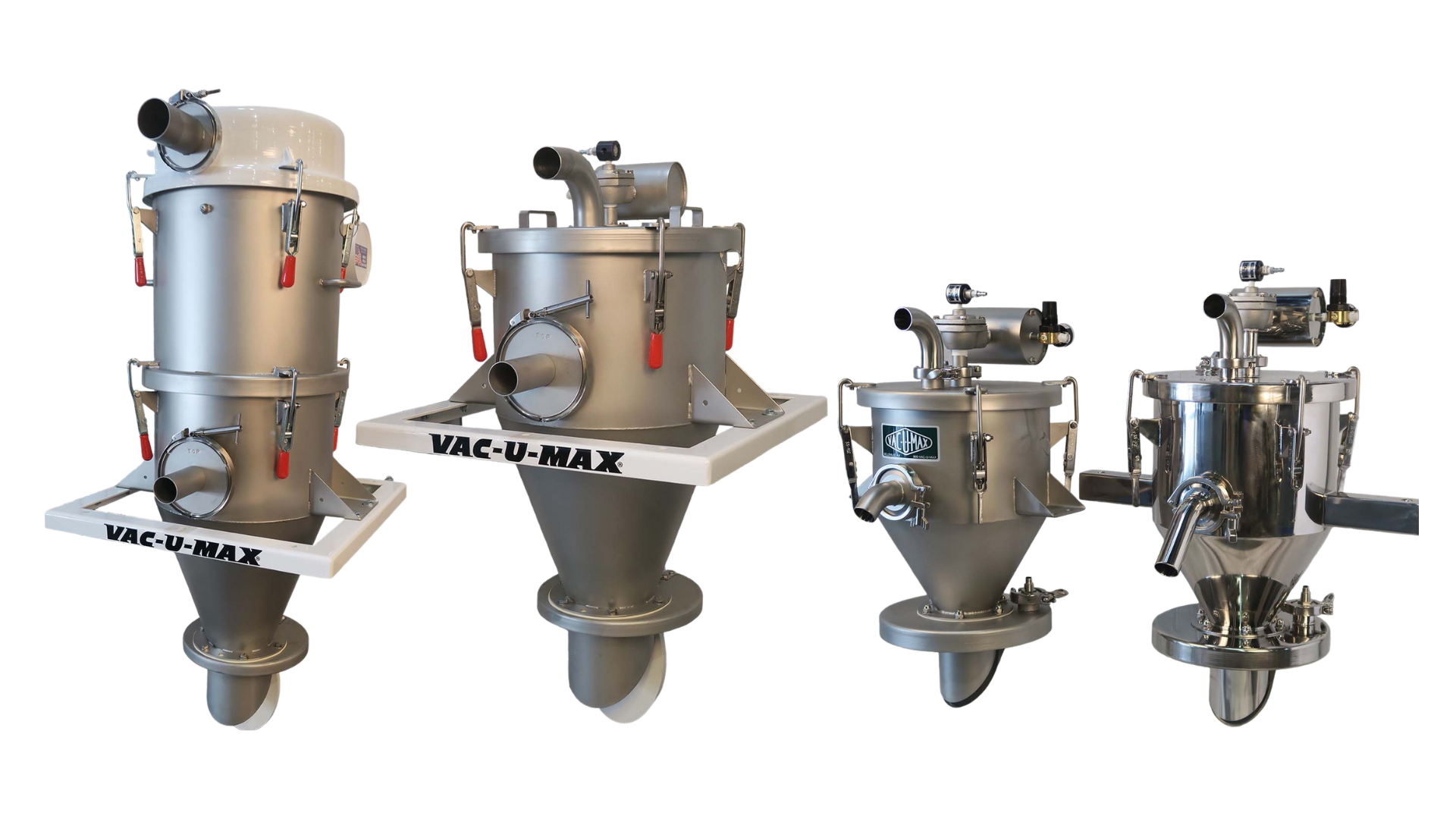

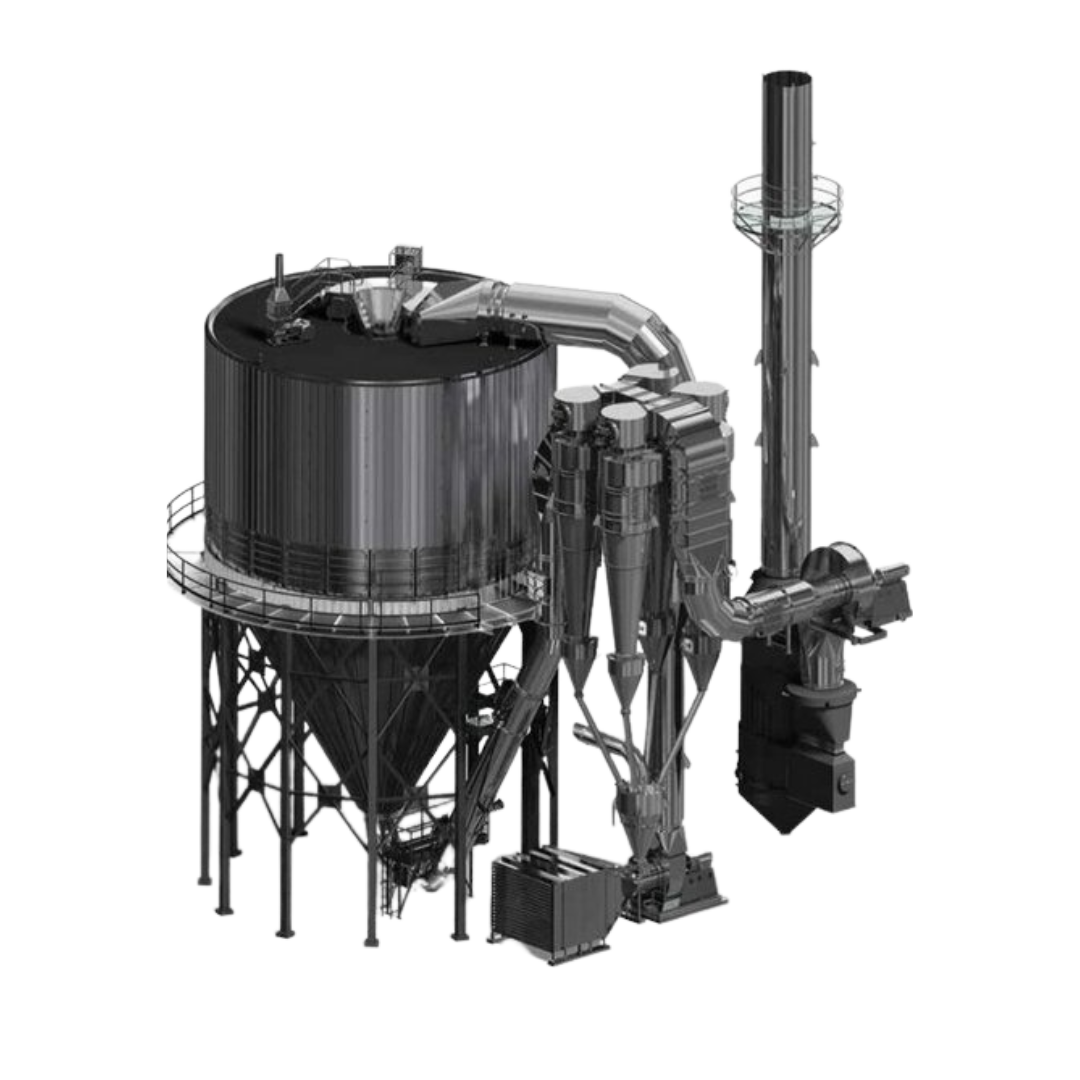

If you're looking to move a variety of materials from one place to another with minimal effort, a conveying system might be perfect.

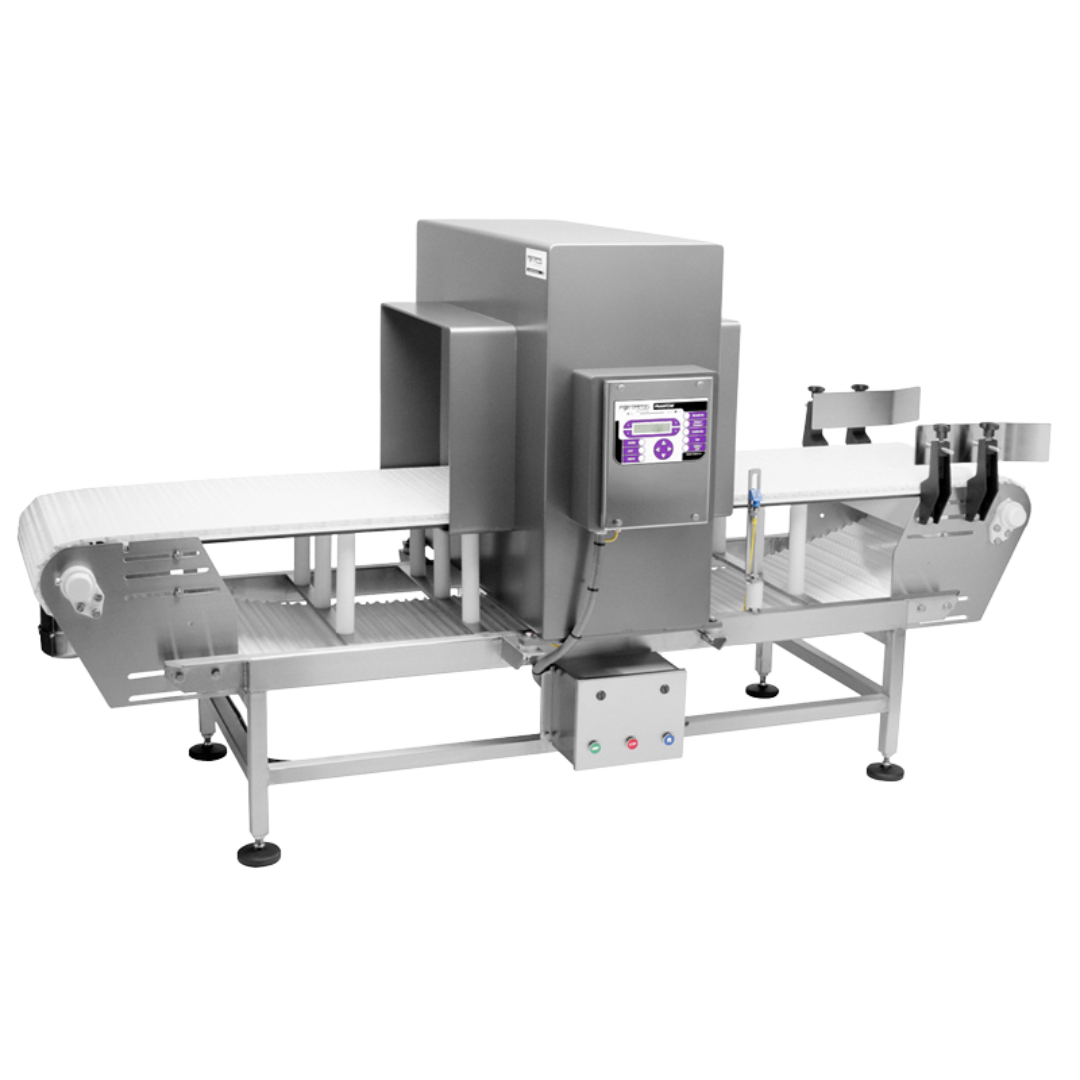

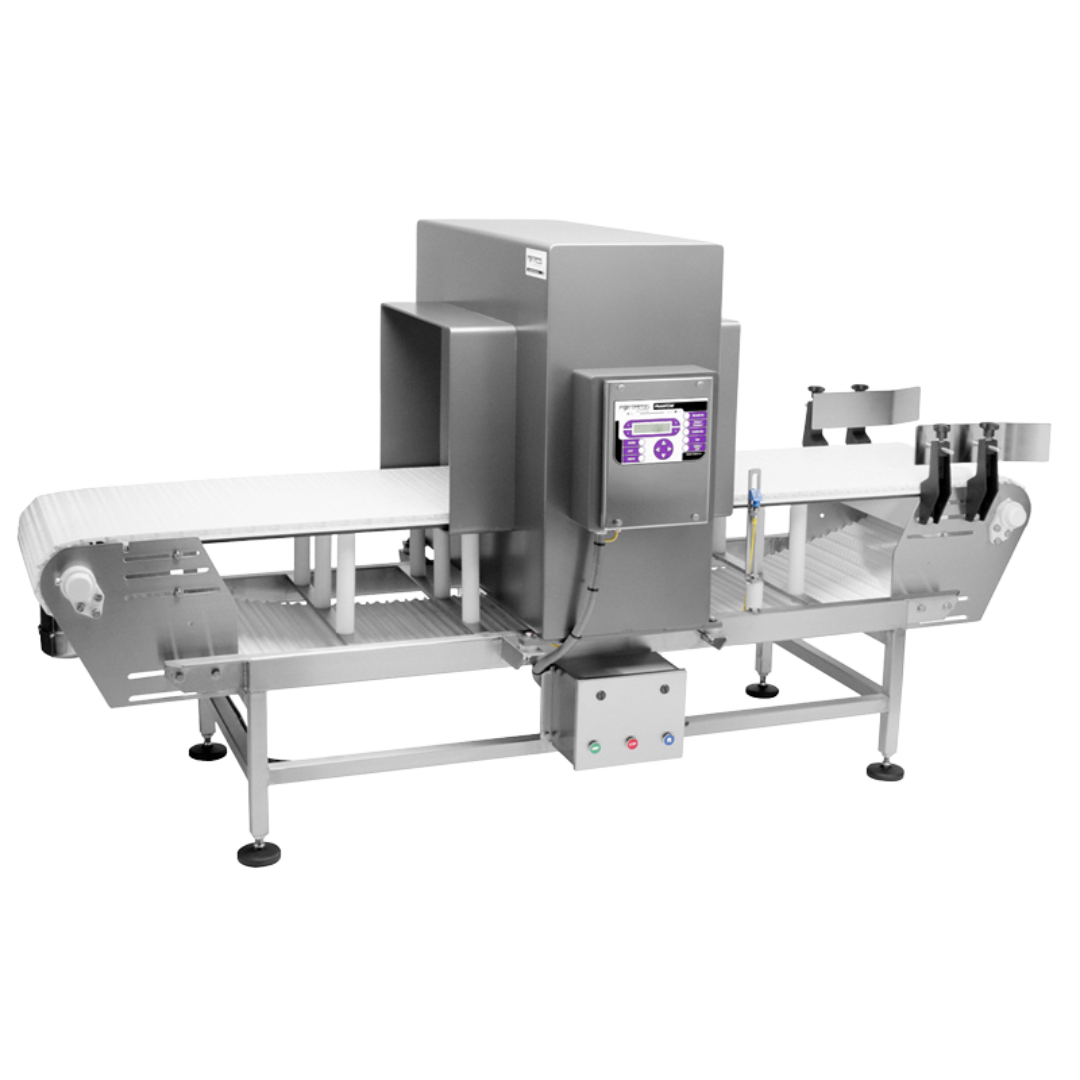

Ensure quality and consistency with inspection and detection equipment that finds and removes unwanted materials.

Explore options for increasing efficiency and productivity with material transporting equipment specific to your needs.

Improve accuracy and uniformity of product with weighing systems that ensure extreme accuracy with weighing your product.

Add reliability and precision to how you control, measure, and disperse bulk solids with metering equipment

Confidently separate your powder and bulk solid materials with sifting and screening equipment.

Combine materials into homogeneous mixtures with ease using blenders and mixers.

Reduce the size of your product's particles with ease and uniformity using mills.

Introducing quality evaporation/drying processes to your production process could help increase efficiency and reduce cost for your business.

Protect your ingredients, operators, and environment with containment systems built to prevent cross-contamination.

Prepare your product for distribution, storage, sale, or use with packaging equipment made to increase efficiency and productivity.

Easily detect unwanted materials or contaminants using inspection equipment.

Since 1975, Solid Design has been the premiere manufacturer’s sales representatives for power and bulk solids equipment in the Southeast. Our small but mighty team uses our 155+ years of combined experience to continue to be a trusted and long-term partner in sales engineering expertise and application. We provide expert, empirical, and effective engineering solutions to our clients that increase efficiency, safety, and quality in their businesses.

We maintain exclusive partnerships with powder and bulk solids equipment manufacturers such as Acrison, Fortress, NBE, Vac-U-Max and more.