- Pneumatic Conveying, Automated Packaging, & Bagging Systems

- Dilute, Dense, & Eco Phase Conveying

- Rotary Airlock Feeders

- Blower Packages

Weighing Systems

Weighing systems are used to measure ingredients accurately by weight. These systems are used to ensure the right amount of material is dispersed in the location where it needs to be. Weigh systems are known to improve efficiency, boost output and uniformity, and eliminate waste and humor error. You can find weighing systems in most industries including rubbers and plastics, food and beverage, and chemical industries.

In the bulk solids and powders industry, weighing equipment can be broken down into more specific categories based on the needs of your business. Some of the most common types include:

A checkweighing system, also referred to simply as a checkweigher, checks the weight of a product while in motion and rejects any product that is over or under the weight guideline as set by the operator. Checkweighing systems are a highly effective way to meet demand and reduce giveaway in production lines where quality and safety are of the utmost importance. Checkweighers are known for their accuracy and precision and thus can be found in highly regulated industries like pharmaceuticals, cosmetics, and chemicals.

Common uses for checkweighers include:

Ensure quality by checking for under and/or overweight products

Ensure compliance with laws and regulations including FDA and USDA reporting guidelines

Classification of products in weight grades

Measure and report efficiency

A batch weighing system is designed to weigh and batch multiple/diverse ingredients. Batch weighing systems have many names in the bulk solids and powders industry that tend to be used interchangeably. These names include: ingredient batching systems, weigh batching systems, automatic batch weighing, etc. There are two main types of batch weighing systems: gain-in-weight systems and loss-in-weight systems.

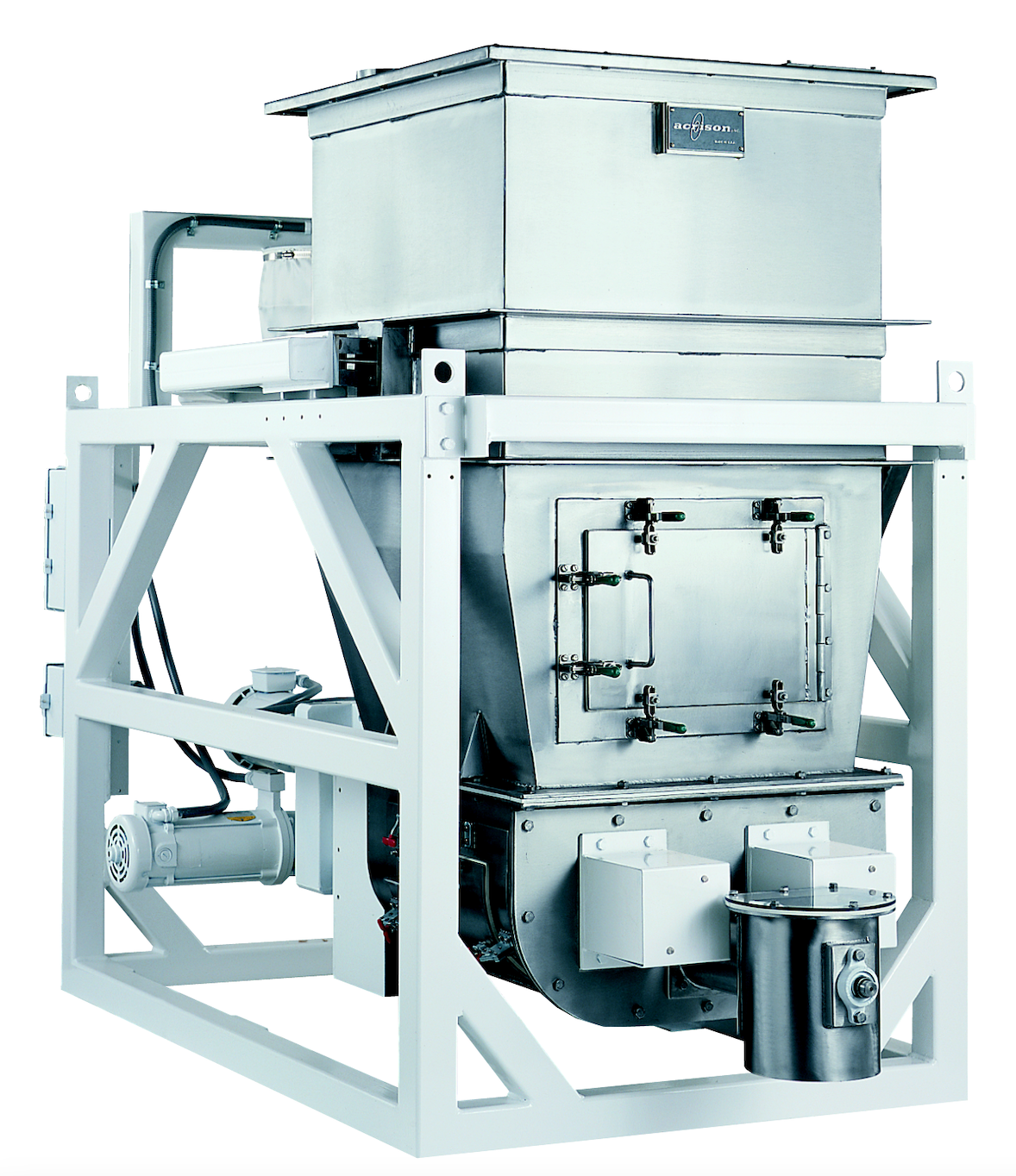

Weigh feeders control the flow of a product by measuring and feeding products on a continuous basis. Feeders are commonly used to control bulk material flow rate into a process or to blend products on a continuous basis. There are two main types of feeders, differentiated by the way they measure and dispense the material: volumetric feeders and gravimetric feeders.

Weigh fillers are designed to weigh and fill pouches, bags, containers, cartons, etc. Weigh filling machines can be used to package candy, nuts, snack foods, pharmaceuticals, and much more. Weigh fillers quickly feed the product into the bin until the amount delivered gets close to the weight desired. It then slows down to a trickle feed to deliver the accurate final weight selected. Weigh fillers are often used to increase speed and efficiency in a production plant.

In most industries, success depends on adhering to strict production requirements. Weighing systems ensure extreme accuracy in distribution, compliance with rules and regulations, and batch-to-batch quality control. Advantages of weighing systems include:

Uniformity of product

Increase Productivity

Retain Product Quality

Cost Saving

With over 155+ years of experience, our team has designed many weighing systems for our clients. We maintain exclusive representation partnerships with the best weigh machine manufacturers including: