- Crushers

- Sieves

- Fine Size Reduction

Grind & Mill

Grinding & Milling Systems

What is milling? Are milling and grinding the same thing?

Milling is the process of reducing the particle size of a product using mechanical technology. Basically, milling places the particles under pressure which, in turn, breaks the particles into reduced parts. Milling is a key process used to transform bulky, oddly sized, and/or oddly shaped particles into uniform, smaller particles for production.

Milling is known by many names such as: size reduction, micronization, milling, pulverizing, jet milling, air milling, or simply grinding. While there tends to be small nuances between the terms, generally these are used interchangeably to describe particle size reduction.

Principle Partners Include

What are some examples of a milling machine?

There are a plethora of milling equipment (mills) that can be used for size reduction. Oftentimes, milling technology can be broken down into three main categories for powder and bulk solid reduction: rolling, impacting, balling, and wet milling.

-

Rolling Mills use two rollers spinning in opposite directions to feed the particle through the roller. Between the two rollers, the product is compressed and forced into its reduced size.

-

Impacting Mills use the force of impact against a solid surface to reduce particle size. Types of impact mills include pin mills and hammer mills.

-

Balling Mills use drums filled with a grinding mechanism, such as ceramic or metal beads, to reduce the size of your product. As the mill is rotated, the beads in the drum tumbles with your product to reduce size.

Within these categories, mills can be broken down even further. From crushers and sifters to blenders and cutters, here are some of the most common milling machines we’ve seen:

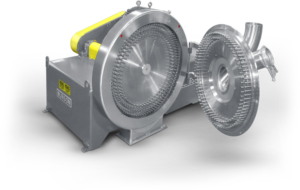

- Pin Mills reduce bulk materials into narrow particle size ranges without the need for screens, hammers, knives or rolls. Instead, it relies on material impacting hundreds of pins thousands of times as it travels from the center to the periphery of the milling chamber.

Lump Breakers reduce compacted, lumpy and agglomerated materials from silos, handheld sacks and bulk bags to their original particle sizes and flowability, making them suitable for downstream processing and/or conveying.